Commercial marine coatings are expected to continue repelling biofouling for 4 to 5 years or more, and it takes that same amount of time to prove that new coatings are effective.

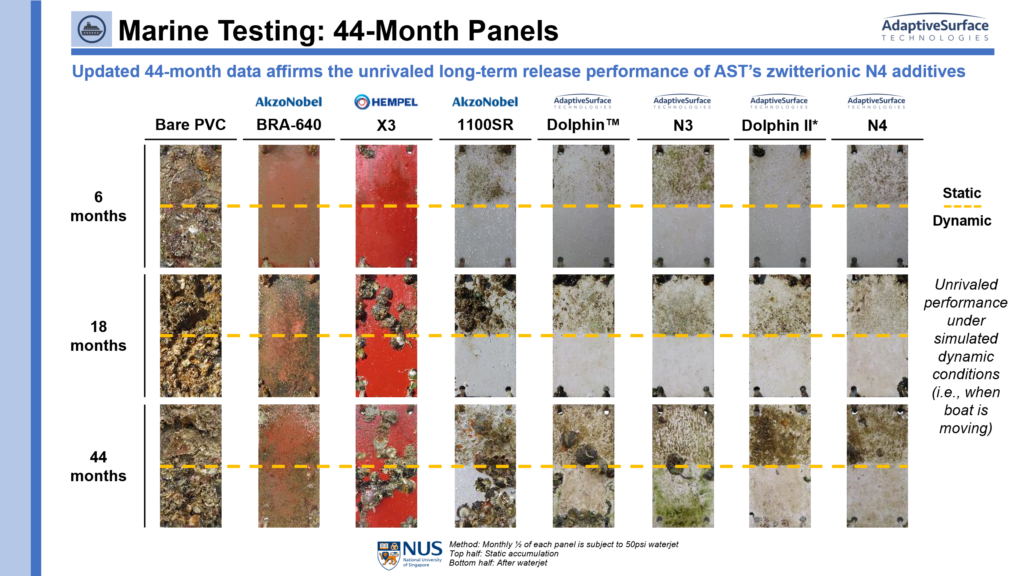

As of now, AST’s marine coatings have been subjected to 44 months of exposure testing, and they continue to outperform the leading commercial foul-release coatings, as shown in the figure below.

This testing has been underway since 2019, conducted by an independent third party at the National University of Singapore (NUS). During testing, AST’s coatings are compared with two market-leading foul-release coatings, Intersleek 1100SR and Hempaguard X3.

Every month, half the panel is washed with a low pressure (50 psi) waterjet designed to simulate the motion of a boat. All of AST’s coatings under test performed better than the commercial controls at 18 and 44 months, especially under these dynamic conditions.

These coatings represent a mix of commercial and experimental variables.

Specifically, SLIPS® Dolphin is AST’s first-generation marine coating, made from commercially available raw materials. The test variable labeled Dolphin II is a second-generation coating from commercial materials that hasn’t yet been launched.

Finally, SLIPS® Foul Protect N3 and N4 are AST’s next-generation coatings made from our own proprietary surface additives. In particular, the N4 zwitterionic additive exhibits a level of performance never before seen in a non-biocidal foul-release coating.

AST is now working with corporate partners to bring coatings based on our proprietary N3 and N4 additives into the commercial marine market, leveraging the reach of a larger-scale operation.

In the meantime, AST is still manufacturing and selling our SLIPS® Dolphin product for the recreational market, and we expect to launch a new version of that product later this year.

Stay tuned!