Products in Development

AST’s proprietary Surface Active Polymer (SAP) additives stratify to the surface and create hydrophilic domains within a hydrophobic matrix. Originally developed to repel marine biofouling, these SAPs have also shown promising performance in a variety of other critical applications. To date, the most significant developments have been for anti-ice applications, thanks to support from a U.S. Air Force SBIR contract.

Ice accumulation continues to be an unsolved and costly challenge across industries ranging from energy to infrastructure and transportation. AST’s proprietary additive packages have shown promising results in a variety of coating systems for the delay of frost accumulation and the reduction of ice adhesion forces.

- Frost forms on the control by -7°C;

- AST coating frosts 6 minutes later at -10.5°C, showing a drastic change in deposition behavior

- Further testing down to -20 °C reinforces the unique effect occurring on AST surfaces

- AST surfaces at -20°C frost slower than control at -10.5°C

AST Prototype Icing Performance at -20C (2x speed)

AST’s coatings significantly delay the onset of frost formation compared to uncoated aluminum. Condensation droplets freeze individually, instead of as a continuous sheet.

AST’s anti-ice coating development is based on additives from our existing non-toxic marine coating that was commercially launched in 2019. Our SLIPS® Foul Protect™ additives reduce the adhesion and persistence of unwanted biological fouling by creating heterogeneous surfaces that strongly interact with and hold sea water. The presence of multiple chemistries on the surface, in addition to the surface ambiguity created by hydration, confuses organisms like barnacles that would otherwise attach to the surface. These same properties make it difficult for ice to strongly adhere by disrupting nucleation and crystal growth at the interface and can delay frost formation.

AST is fine-tuning these additives and coatings for anti-ice challenges, optimizing properties for frost resistance as well as application-specific longevity. By combining a mechanically durable low surface energy binder system with AST’s patented self-stratifying additives, a functional coating with strong anti-ice properties can be created while maintaining robust mechanical properties.

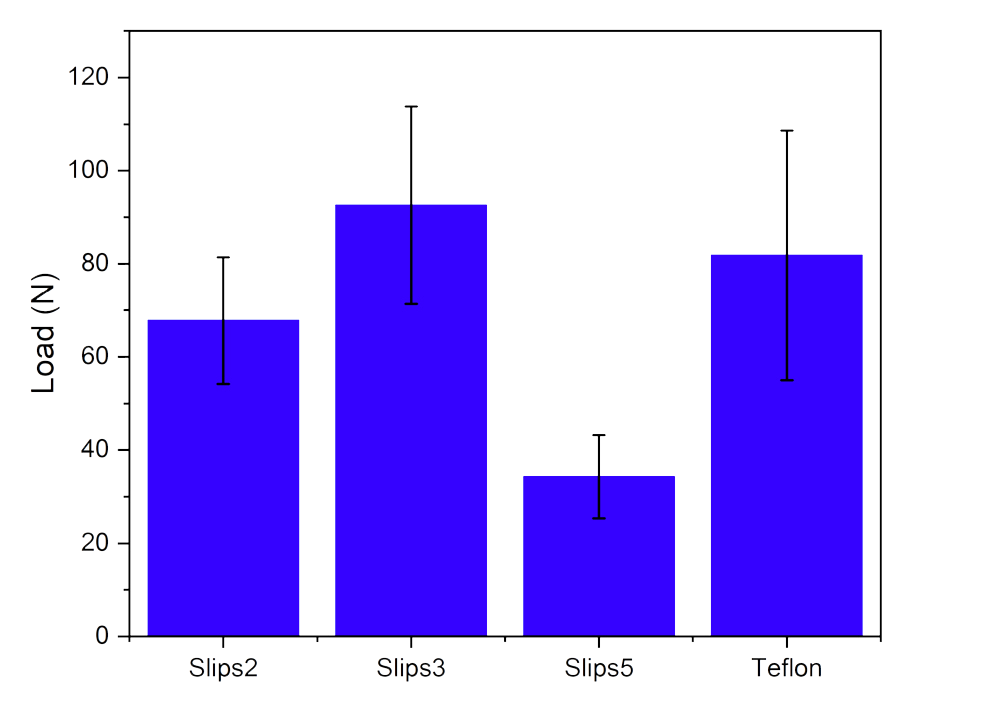

The average and standard deviation of the maximum load at delamination for each of the three SLIPS coatings.

Values for Teflon coatings are included for reference.

AST is welcoming additional partners who are interested in evaluating our prototype anti-ice technology in commercially relevant applications.

Further Applications for AST Additive Technology

In addition to our marine and anti-ice coating development, AST is exploring additional applications where our novel surface functionality creates repellent or easy-cleaning effects. These are earlier-stage developments which AST has begun exploring via additional prototype samples.

MEDICAL

Reduced Fouling

Low Protein Adhesion

ANTI-MOLD

Low Growth

Low Adhesion

ANTI-VIRAL

Disinfectant Reservoir

Longer Surface Disinfection

REPELLENT ARCHITECTURAL PAINT

Low Adhesion

Self Cleaning

ANTI-SCALING

Less Mineral Adhesion

Easy Clean

ANTI-FOG

Reduced Condensation

Easy Clean